Fundamentals of Steam Turbines – A One Day Course

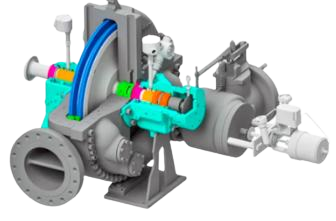

The goal of this training is to make you familiar with the steam turbine including basic operation, critical parts, and procedures for repair, installation, start-up, and operation. By learning this information, it will give operations, maintenance, and engineering a better idea of what to expect from your turbine operation.

- Section I

Basic history of steam turbines

Why they are used in the Petrochemical Industry

Basic application and where they are used

Basic design criteria and why there are various sizes of turbines

How to find critical information on each OEM manufactured turbine

Governor operational principles

Steam path through the turbine

Critical parts of the turbine and how they function - Section II

What to look for prior to removal of the turbine

What to look for during the basic disassembly of the turbine

Basic inspection and repair practices

Major ideas to observe during the repair and case studies

Assembly tips and practices

Installation procedures and practices Installation procedures and practices with case studies

Start-up procedures and where to find them

- Training is held every 4th Thursday of the month starting at 8:00am and concluding at 4:00pm

- Estimated training time: 1 day (including facility tour).

- This training program is a hands-on course designed for plant machinists, operators, maintenance personnel, maintenance

engineers and supply chain professionals. - Cost of the program is at no charge.

- Each trainee will receive a certificate to apply towards PDH or CEU credits.

- Location: Revak Keene Turbomachinery 12204 W Fairmont Parkway, La Porte, TX 77571.

- Limited availability

RSVP: Ashley.dutton@revakkeene.com

Hosted by Randy Tye

RKTM’s lead trainer with over 40 years of Petrochemical Industry

experience and passionate about turbomachinery